Products

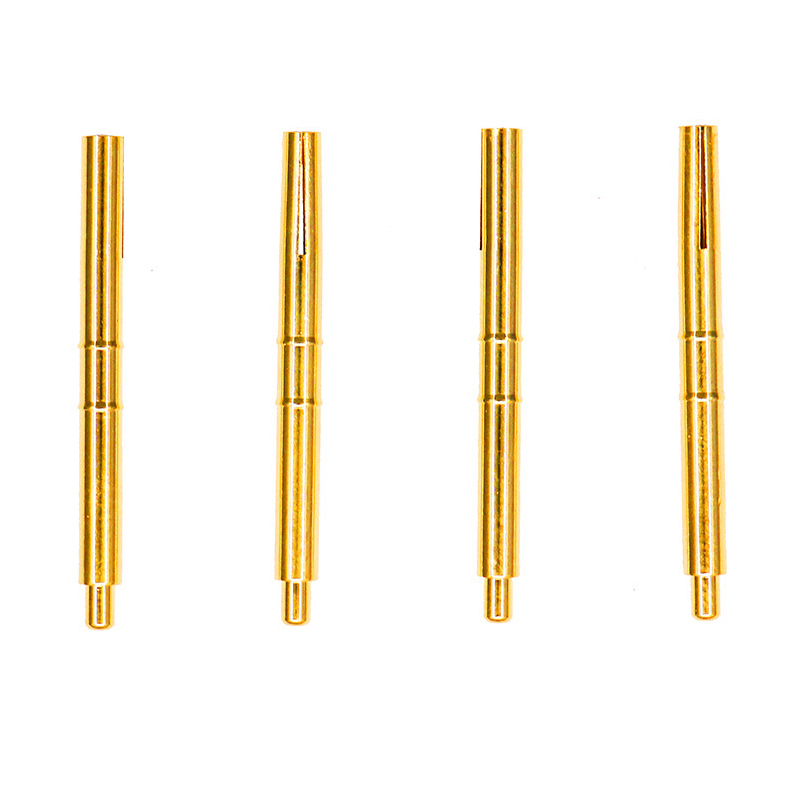

Standard SMT Pogo Pin

Five Advantages Of Products

- professional for ODM & OEM orders

- Barrel & plunger: Brass/Be-Cu/Phosphor bronze

- Plating: Gold plated (According to customer requirements)

- Spring: SUS/SWP

- Life test: 20,000~1000,000 cycles

Product Details

We are leading manufacture & exporter of supreme quality Brass pins & sockets. We produce a big variety of brass pin like Brass Socket Pins, brass Plug Pins, Brass Charger Pins, Brass Auto Electrical Pins, Brass Contact Pins and Brass Neutral Switch pins which are made from copper zink alloy as per customer requirements. This Pins are used in many industries like Automotive, Electrical & Electronics, Comunication & Telecom. SMT/SMD POGO PIN

SMT/SMD POGO PIN

It is also called flat bottom pogo pin. There is a common pogo pin connector.In our daily life,the connector already exists on many PCBs,as the name suggests,its barrel bottom is flat,and it is soldered to the PCB by surface mounting technology.

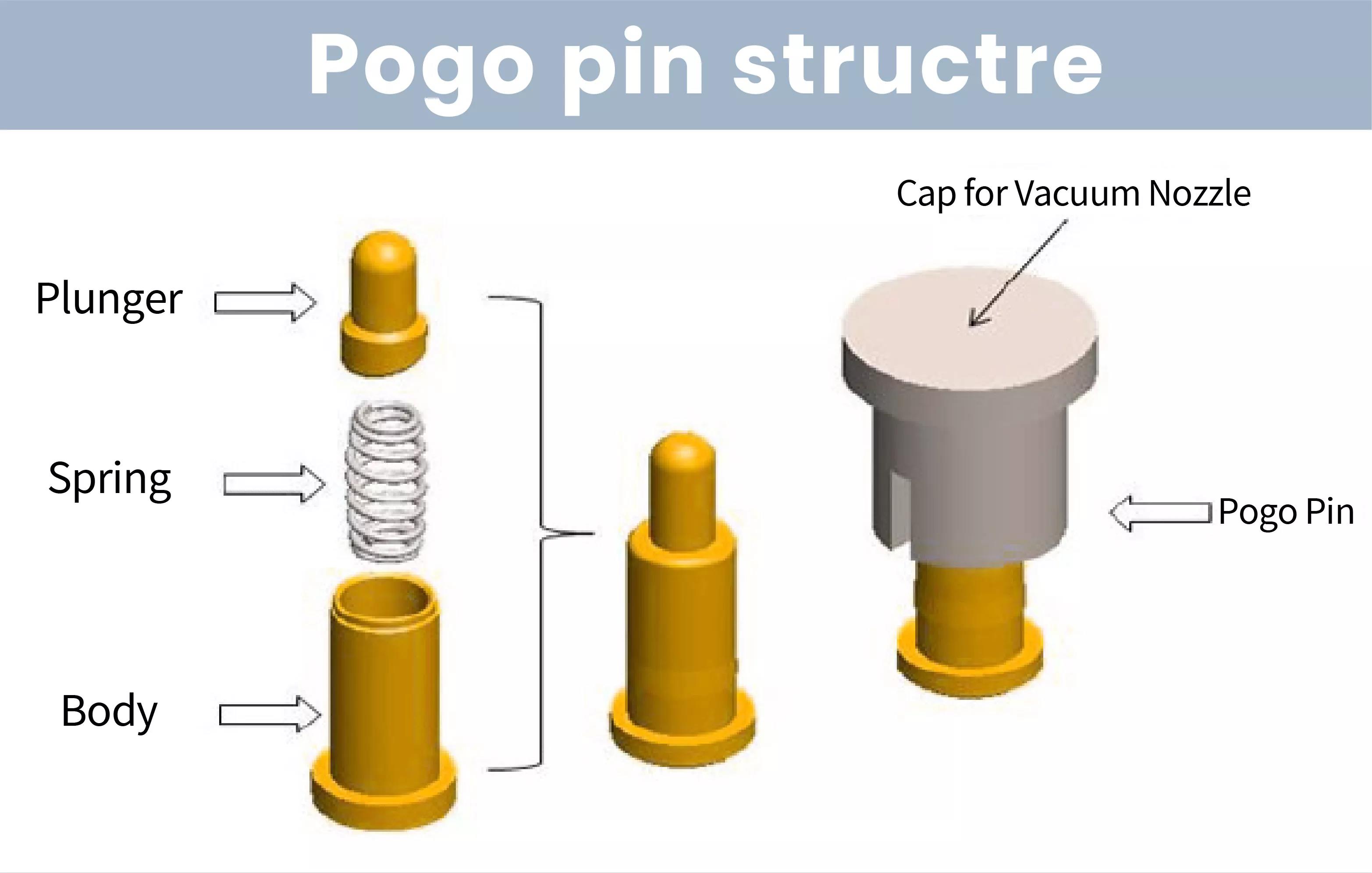

What is the stucture?

The main part of the SMT/SMD pogo pin can be divided into three parts:plunger,barrel(body) and spring.The most obvious feature is that the bottom shape of the barrel is a flat bottom.

The common internal structures can be divided into up three-piece type is composed of the flat bottom barrel,plunger,and spring.On the basis of the three-piece type,a copper ball or steel T-pin is added between the spring and the plunger.

Compared with the three-piece structure,the current resistance of the four-piece structure is significantly improved.

The benefits of SMT/SMD POGO PIN

Compared with traditional connectors, it can be quickly soldered on the PCB through SMT technology, saving a lot of space on the PCB. The parts of the SMT/SMD pogo pin are processed by turning and do not need a mold.It is easy to realize rapid change and switching in the process of design and processing, which effectively reduces the production cost of the pogo pin connector. Moreover, it also has the characteristics of stable contact and a long life cycle.

How is The Pogo Pin Connector Used In Electronic Devices and Circuits?

In electronic equipment or circuits, a flat bottom pogo pin is usually soldered to the PCB through SMT surface mounting technology, and then assemble the soldered PCB to the electronic equipment. For the products of smartwatches and smart bracelets, the common assembly method also includes the assembly of a flat bottom pogo pin after inserting molding.

Are There any Potential Downsides to Using It?

Compare with other types of pogo pins, the soldering strength of SMT/SMD pogo pins is relatively weak. The lateral thrust that it can bear is relatively small. In addition, when the height required by the application is less than 1.5mm, it is difficult to realize.

How To Choose The Right One?

Are you choosing a connector with a specific diameter and size? Dongguan Promax has always been good at designing products for specific applications. Whether we change its diameter, length, or spring force, we can accurately produce the required pogo pin connector. Welcome customization!

Guangdong corecon precision Industry Co.,Ltd.

Contact Person: Jelly

Telephone: 13316669302

Landline: 13316669302

Company Address: Building 1,No.369 Jinjiang Road,Chang’an Town,Dongguan City,Guangdong Province.

Website: coreconltd.us764.com

Previous: spring loaded pin